Thermylene® Brochure

Innovative Polypropylene Compounds for Enabling Applications

Join us for our “In the Business of Better” Webinar Series 2021

Register Now!Thermylene® represents Asahi Kasei's family of award winning chemically coupled glass reinforced polypropylenes (PP). When chemical coupling technology is applied to glass fiber reinforced polypropylene, significant improvements are seen across a number of key physical attributes.The enhanced compound properties yield an attractive balance of cost and performance compared to conventional engineering thermoplastics.

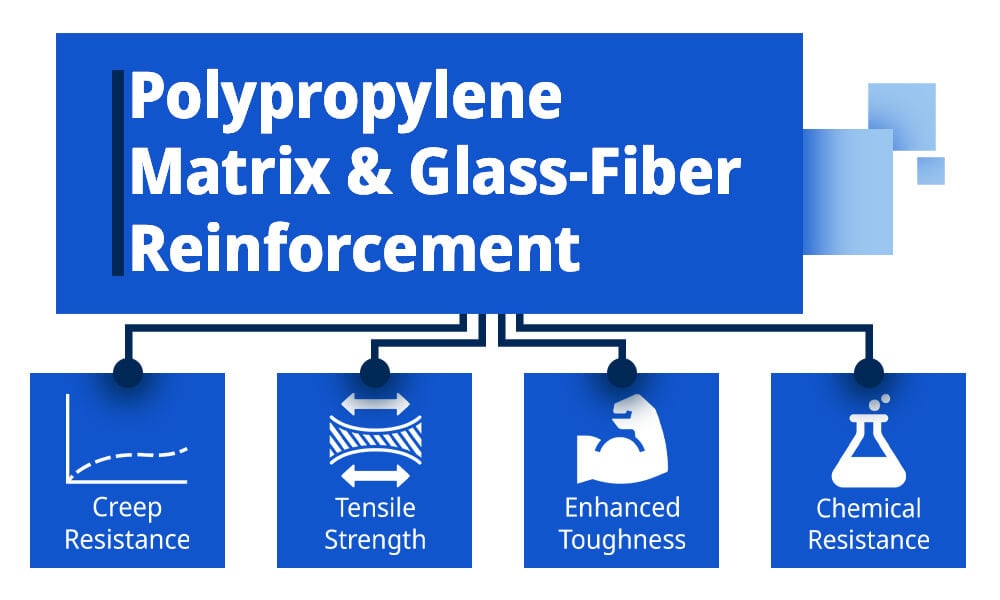

What Is Glass-Reinforced Polypropylene?

Glass fiber (GF) is the most widely used reinforcement in polypropylene (PP)-based composites as it provides a valuable balance between costs and properties. Glass-fiber-reinforced polypropylene compounds deliver improved strength, structural rigidity and dimensional stability in applications.

The key performance in glass-reinforced polypropylene compounds is delivered by the efficacy of formulation design and polymer fiber interphase. Thermylene® products provide increased durability, strength and stiffness for critical structural components. Glass-fiber-reinforced polypropylene compounds have significantly improved flexural modulus and tensile strength because of superior design and state-of-the-art production technologies applied by Asahi Kasei.

Critical Benefits of Long Glass-Fiber-Reinforced Polypropylene

Thermylene® brand represents our fiber-reinforced polypropylene compounds that go above and beyond traditional polypropylene glass-reinforced commodity products. Thermylene® glass-fiber-reinforced polypropylenes carry the following benefits:Unique Capabilities:

Applications:

Our Thermylene® grades offer the following grades:

Innovative Polypropylene Compounds for Enabling Applications